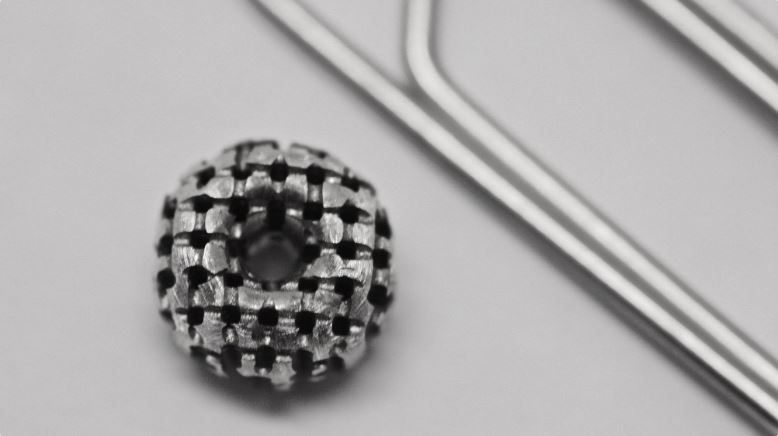

MagSca – Customized, biomimietic Magnesium Scaffold solutions for bone regeneration

2021 Campaign: Personalized HealthTech & 3D Printing

Bone substitute materials often rely on human (autologous, allogenous) or animal (xenogenic) bone grafts. These grafts are expensive and suffer from a lack of control of pore shape and size (at the microscopic scale) and endure a laborious procedure (macroscopic tissue shaping). Although autologous bone provides the best biological constructs, patients may suffer from donor-site morbidity, pain at the harvest region, and additional surgery time/costs. To mitigate these challenges, one of the most exciting areas in biomaterials is the development of novel, synthetic, biodegradable bone substitute implant materials with controlled biomimetic architecture.

Due to excellent biocompatibility, bone-like mechanical properties, and osteoinductivity, Magnesium (Mg) is a particularly desirable candidate for bone scaffolds. The prospect of employing Mg implants as scaffolds for new bone growth and fixatures to hold together bone long enough for physiological healing has enormous potential in regenerative bone surgeries.

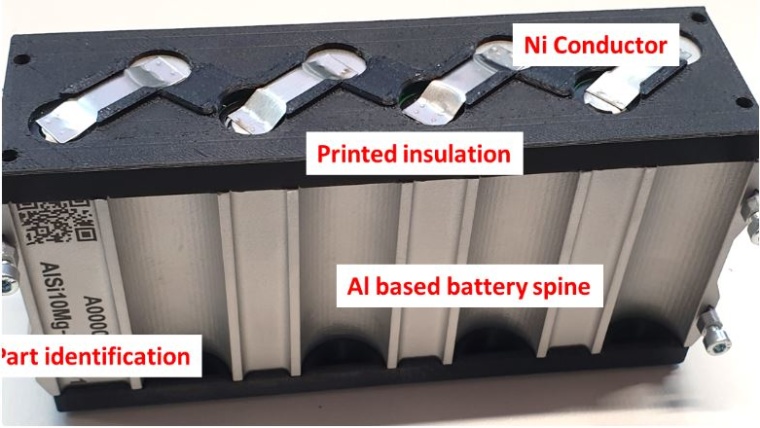

Although 3D printing of Mg scaffolds is being researched, this approach suffers from certain limitations, causing a severe impact on the final part’s composition, accuracy, and density. Hence, the prospective start-up sallea proposes an alternative fabrication method using 3D printed sacrificial templates for Mg biomaterial impregnation. The template can be washed away upon Mg solidification, avoiding further post-processing procedures. The flexibility of 3D printing constructs further allows for complete control of the pore architecture and can be tailored to patient-specific biomimetic geometries. The digital transformation of CT datasets to patient-specific 3D models is a strong competence of the 3D-Print Lab at University Hospital Basel (USB). Through this project collaboration the partner organizations plan to combine the technical and clinical expertise to produce world-class research outputs and clinical practice advancements. Therefore, this project aims to establish a personalized treatment solution by providing a complete digital workflow starting with patient CT, to patient-specific reconstructed 3D model to the 3D printing of sacrificial template, and eventually fabrication of a biomimetic customized Mg scaffold. The respective competencies jointly add the missing link of transforming the workflow of USB into a digital construct model, which can be further processed in the workflow of sallea into a first Mg patient-specific bone scaffold prototype. Eventually, these customized Mg bone scaffolds have the potential to eliminate implant removal surgeries, lower patient pain, risk of infections and reduce the cost of the overall treatment.