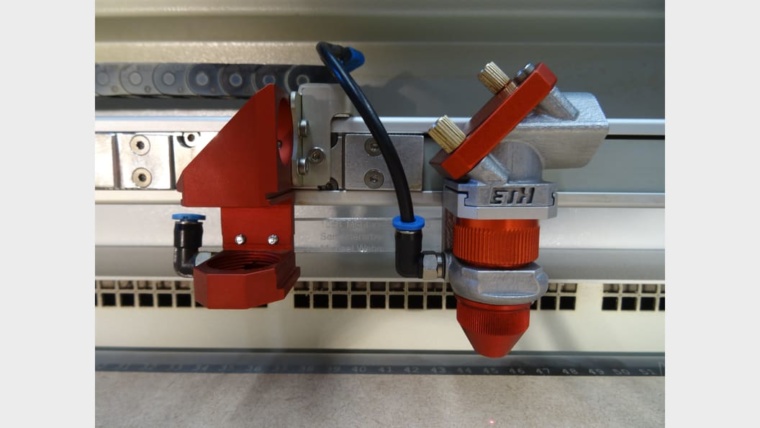

Titanium implants made by Selective Laser Melting

The School of Life Sciences of FHNW operates a qualified Selective Laser Melting process to manufacture medical products in titanium grade 2. Such implants are approved for the use in humans already today.

The School of Life Sciences of FHNW has almost 20 years of experience with additive manufacturing technologies, for 10 years with a specific focus on medical applications. Thereby, it looks at the entire process chain from image acquisition (CT), data processing and 3D modelling over manufacturing and qualification to post-processing and cleaning.

In 2012, titanium structures made by Selective Laser Melting could be used as implants within humans in clinical trials for the first time. One year later, the startup Mimedis Ltd. was founded to further develop these clinical applications. Together with this company, a Selective Laser Melting process to manufacture titanium grade 2 qualified after MDD 93/42 was established and a quality management system after ISO 13485 introduced.