Hybrid tool optimises injection molding

Injection mold with internal conformal cooling additively placed by selective laser melting on the tool base. Reduction of cycle time by 60%.

The company Michael Dewald Kunststoffverarbeitung GmbH in Tettnang (Germany) is an advanced injection molding manufacturer with customer focus in Southern Germany and Switzerland. The company has worked in various areas of mechanical engineering, automotive and electrical engineering. Dewald currently operates 32 injection molding machines and provides all molds within their own toolmaking.

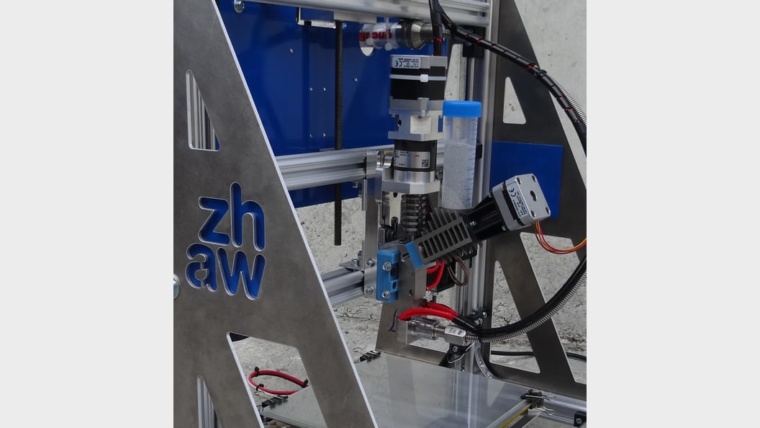

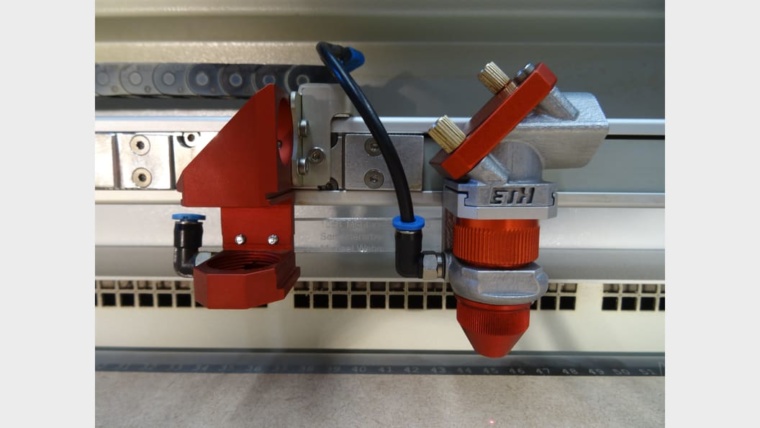

The aim of this project was to replace the existing injection mold for the handle of a bicycle carrier by an additive-crafted tool with internal conformal cooling to reduce the cycle time. Furthermore, the existing conventionally produced tool base plate should be used to limit the additive manufacturing to a minimum.

Through a sophisticated hybrid design the injection mold was optimized with conformal cooling and the cooling was simulated successfully. Was followed by the additive manufacturing by selective laser melting on the base plate. The post processing was made by conventional milling and polishing.

By conformal cooling within the double tool, the cycle time can be reduced by 60% from 55 seconds to 22 seconds. Thus, increased production costs for the tool by the additive manufacturing can be easily compensated.