Weight-optimized galley attachment

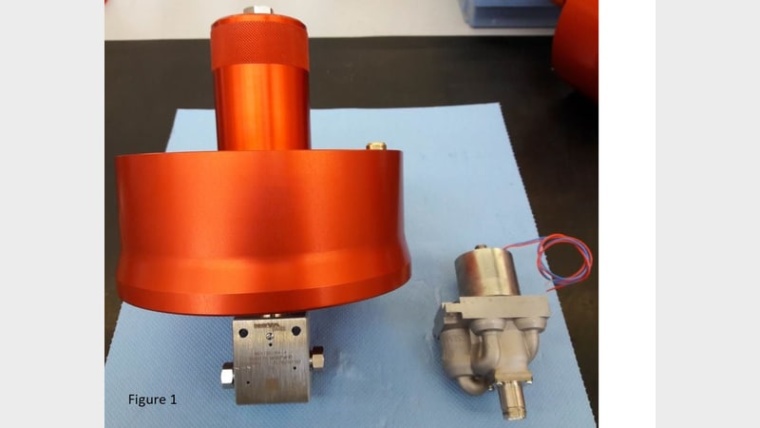

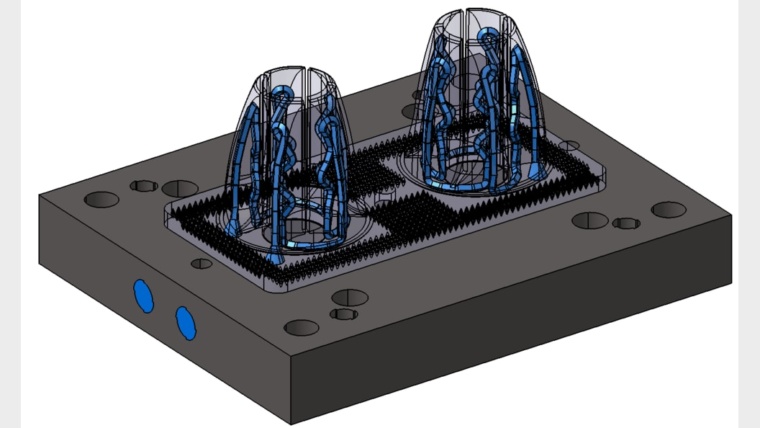

Successful development of a weight-optimized galley attachment for aircraft kitchens through adapted topology optimization and additive manufacturing (selective laser melting).

In aerospace (L&R), each gram of weight determines how much fuel an aircraft consumes and what costs are incurred by the operating company. By means of topology optimization and additive manufacturing, the weights of aerospace components can be reduced, which was not possible with conventional manufacturing technologies in the past.

The example of a weight optimization of a galley attachement shows what is possible with coordinated topology optimization and additive manufacturing, in this case selective laser melting. The implementation of this optimization process shows that the component can be reduced to approximately 18% of its original weight.

Your contact person for this showcase:

Dr. Andreas Kirchheim

ZHAW Zürcher Hochschule für Angewandte Wissenschaften, ZPP Zentrum für Produkt- und Prozessentwicklung

Phone

+41 589347625

E-mail

andreas.kirchheim@zhaw.ch