SON – Shut-Off Nozzle for Large-Scale Polymer Extrusion

2021 (Autumn) Channel: General ideas and needs in the field of additive manufacturing

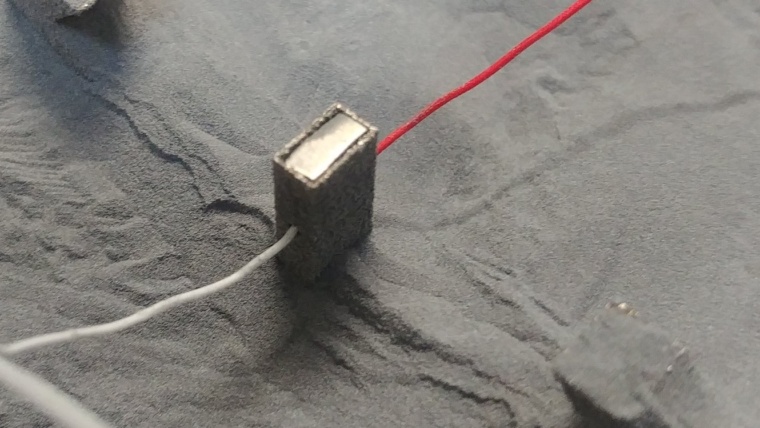

Our idea is to develop a compact and lightweight shut-off nozzle to control the material flow during pellet extrusion (stop and go) and enable a resource-efficient 3D-printing robotic pellet extrusion process.

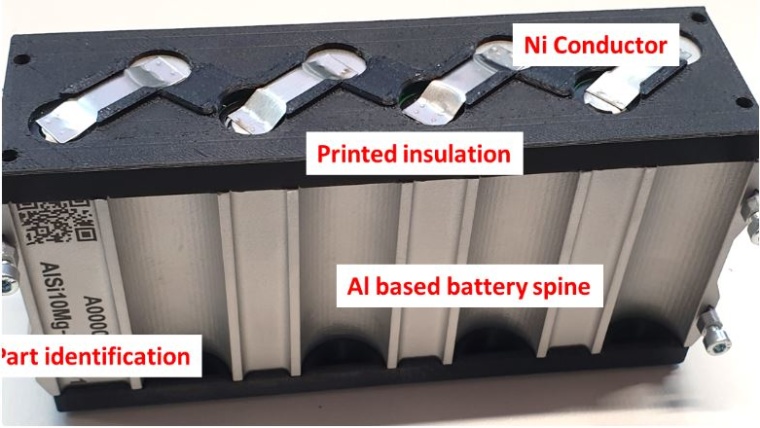

Recently, multiple hardware manufacturers (CEAD, Massive Dimensions, Dyse Design, Xtrusion, Cosine, etc.) are providing tool heads for robots for using pellet extrusion instead of filament-based polymer extrusion to increase the amount of extruded plastic (from 0.2 to 10kg) while reducing material costs (from 50 to 5 CHF/kg). These tool-heads can be compared to a down-scaled version of an injection molding machine.

Injection molding, a process where pelletized thermoplastic materials get injected into a mold is using shut-off nozzles to control material output. Shut-off nozzles are commonly used to control the nozzle closure during pressure build-up and during mold changing. The available solutions are not suitable for pellet extrusion 3D printing as they are designed to withstand much higher pressure and therefore result in large and heavy equipment (compared to available pellet extrusion 3D printing systems).