Performance increase of additively manufactured parts due to functionalization integration

2021 (Autumn) Channel: General ideas and needs in the field of additive manufacturing

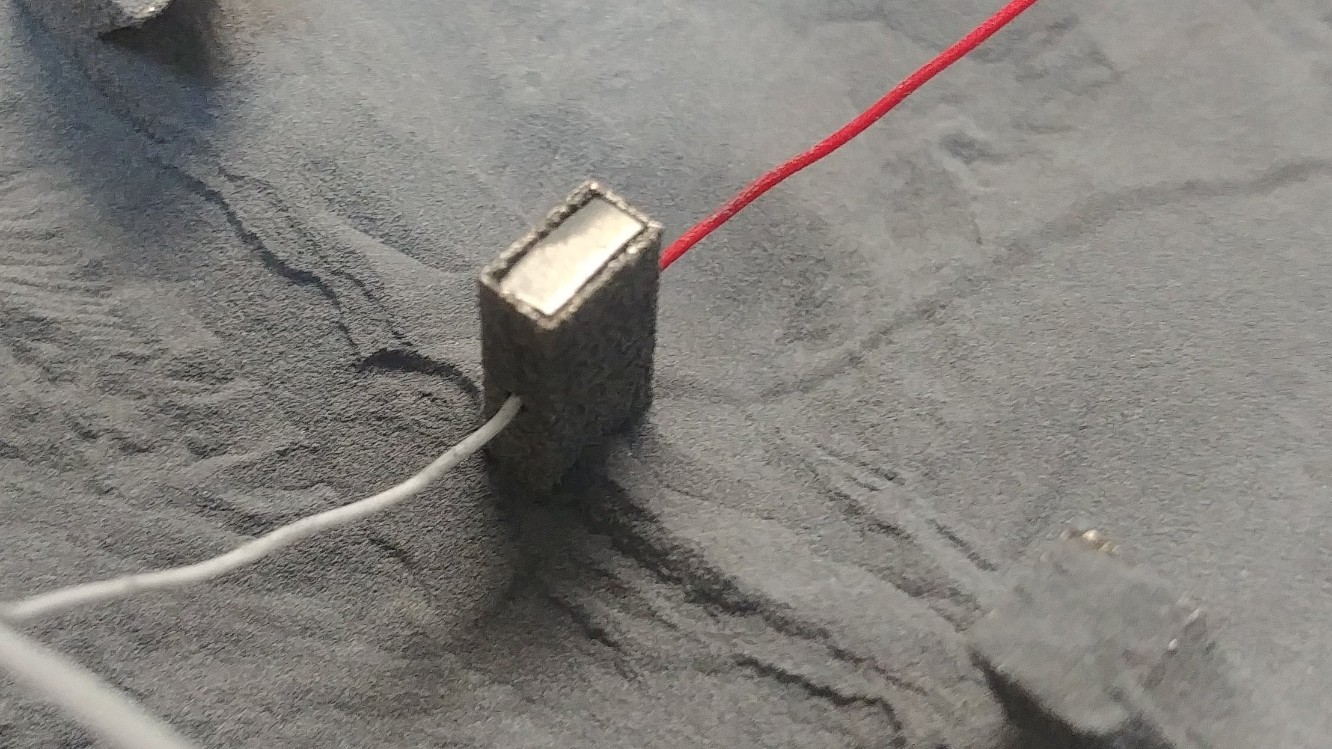

Laser-based powder bed fusion of metals (PBF-LB/M) is the most commonly used additive manufacturing process for fabricating complex metal parts by selective, layer-wise melting of metallic powder using a laser beam. This manufacturing technique can easily fabricate parts with complex geometries that cannot be fabricated using conventional manufacturing processes. These parts with complex geometries are generally used by a broad industry e.g. aerospace and advancement in functionalization of additive manufactured parts is highly beneficial to these industries. The integration of piezoelectric materials offers a wide range of applications. However, there are only few manufacturing and integration techniques to full fill the challenging requirements of piezoelectric materials. They need to be pre-stressed to guarantee function during operation conditions and they are brittle and sensitive to thermal influences. After 1.5 years development time there is a solid basis of integration concepts which has high potential in further development solving urgent industry needs.