Additive Manufacturing of Intelligent Solenoid Valve (iSV)

Additive manufacturing (AM) enables to place various sensors in specific areas of a part in close proximity to the location of interest. This showcase presents the design and manufacture of miniturized, intelligent and Industry4.0 ready high-pressure H2-valves with integrated sensors.

High performance pressure valves

Valves are components which are ideally suited for additive manufacturing since conventional manufacturing technologies reveal clear limitations when flow-optimization and complex designs of the channels get important. Additive manufacturing, Selective Laser Melting (SLM) in particular, facilitates the production of highly complex geometries combining flow optimization with miniaturization as well as minimum wall thicknesses, i.e. lightweight design. SLM furthermore facilitates the embedding of sensors into valves, to reach the goal of intelligent components covering Industry 4.0 aspects and digitization. This is especially important for security reasons in mobility hydrogen gas stations, where these intelligent iSV valves shall be designed for.

Inspire icams and inspire pdz, together with Nova Werke AG performed a CTI project for the development of such intelligent valves.

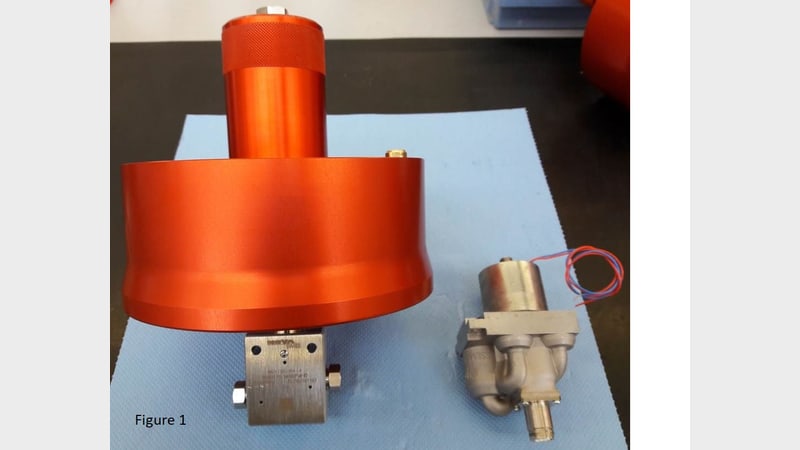

Figure 1 shows the former valve (left) without any intelligence, and the SLM manufactured intelligent Industry 4.0 ready Nova iSV valve (right). A main aspect of this tremendous size reduction is the replacement of the pneumatic actuation (red part in Fig. 2, left) by a fully integrated magnetic coil. Furthermore, wall thicknesses are reduced to the minimum that is still capable to withstand internal gas pressures of up to 1000 bar, and the valve channels are flow-optimized, improving concurrently the performance of the valve by high flow coefficients Cv that cannot be achieved with traditional manufacturing technologies.

Intelligence by sensor integration and additive manufacturing

With respect to the intelligence of the valve three different sensors are embedded during the manufacturing process. While two temperature sensors monitor the change in temperature on either side of the main valve, a Hall effect sensor monitors the position of the piston. These sensor data are of significant importance for security reasons, and for predictive maintenance.

An innovative hybrid manufacturing approach is developed to keep the total production costs in a competitive range to conventionally manufactured valves. This builds the starting base for a successful industrialization of the iSV valve by Nova Werke AG, with close support of inspire.

Your contact person for this showcase:

Dr Adriaan Spierings

inspire AG

Phone

+41 0712747319

E-mail

spierings@inspire.ethz.ch