Additive manufacturing for high-end cameras

ALPA Capaul & Weber AG develops high-end medium format cameras. Starting from customized lens shades, the company successfully implemented additive manufacturing in a step-wise manner into its product portfolio.

ALPA Capaul & Weber AG from Zurich specializes in the development of high-end medium format cameras. The previous Additive Manufacturing Report in 2016 had already presented this company with its products. The focus lay on high-variety lens shades for modular camera systems. Lens shades are mounted at the front of the camera in order to prevent reflections in the lens during complex lighting conditions.

Using additive manufacturing enables many advantages to be realized for this kind of application. The design freedom of generative manufacturing allows fabricating modular, individually adapted lens shades. These are customized according to the angle of view, lens, and sensor of the camera. Different configurations are created automatically based on parametric CAD models. The production is carried out by laser sintering of thermoplastic polyurethane (TPU). The comparatively light material has flexible, rubber-like properties. In addition, its durability and water resistance makes TPU perfect for the regular use of the cameras.

In this way, the company was able to offer its customers a wide range of easy-to-handle lens shades, of which the shape is precisely adapted to the individual camera system. This allowed the company to add a number of variable products to its portfolio without having to make major investments in advance. This kind of flexibility would hardly be possible with another production method.

Since the last report, ALPA Capaul & Weber AG has been working consistently on expanding the use of additive manufacturing in its product portfolio. Over the last two years, several further developments have been implemented, which are outlined in the following. From the company’s point of view, it is described what experience was acquired and how it successfully implemented additive manufacturing.

ALPA managed the introduction of AM technologies in a step-wise manner. Such an approach aims at increasing the complexity of targeted applications with an increasing understanding of the whole AM ecosystem. It is important to emphasize that lens shades represented the first step into additive manufacturing. Similar parts tackled in the early phase include modules such as covers, holders, or other accessories. Such type of components are not function-critical or highly loaded, nor do they have a very complex interface. For such parts, additive manufacturing is advantageous and offered a clear application case with customer benefit. In this first step, the aim was to gain initial experience, generate basic expertise and establish a first process chain for additive manufacturing. Besides knowledge in “Design for Additive Manufacturing”, this includes choosing a suitable manufacturing process with the right material and post-processing technology as well as establishing a collaborative relationship with suppliers.

This first process chain covered three important areas, namely identifying the right application with a suitable design, production with a robust supply chain together with partners, and validating the business case. Based on this, the second step of implementing additive manufacturing was to increase the complexity in all three areas and further improve the process chain.

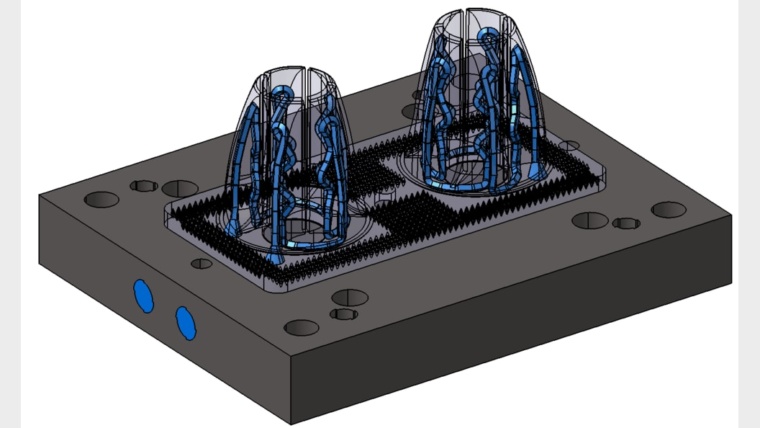

For instance, regarding design, functional assemblies with a higher degree of complexity than in the first phase were developed and additively manufactured. An example is the metric photogrammetry camera ALPA 12 add|metric. Photogrammetric techniques allow fast, contactless and precise acquisition of complex geometries. For this purpose, photogrammetric applications require increased mechanical stability. Using laser melting of fiber-reinforced polyamide (PA3200 GF), digital medium front cameras were modified and optimized for such applications. The ALPA 12 add|metric was successfully tested and resulted in a high accuracy for photogrammetric applications. The development process benefited not only from the design freedom of additive manufacturing, but also from short innovation cycles and cost advantages in small series production.

Based on the successful results in the first and second phase, the aim of the third phase was to systematically integrate additive manufacturing into the product development processes and adapt them accordingly. The company recognized that the design approach could be further improved by implementing agile hardware development principles. In this context, it is also important to respond to new market requirements. Trends include the emergence of new markets such the increased demand for customized products, the rapid development and adaptation of components for various camera systems, and the increased use of video in addition to photography in advertising,

One example is the agile development of a high-end video camera for a Hasselblad H6D digital back. In several short sprints the video camera with its features like mounts for camera and battery was developed. Several different prototypes were fabricated by means of laser sintering. After each sprint, lead users tested the developed product features. Based on usability tests, these were further improved and re-tested. Product improvements are thus incrementally released and quickly validated. The feedback was used to fine-tune the product. The total time-to-market was around six months.

In retrospect, the showcase successfully demonstrates how additive manufacturing can be introduced in a company within three phases. First step is to set up a complete process chain for rather simple designs and non-critical applications (one material, one process), which offer a clear value-adding benefit for additive manufacturing. The second step is aimed at gradually increasing its complexity regarding the relevant areas e.g. new materials, more complex designs, different post processing combinations, order processing. Based on the acquired knowledge, the third phase seeks to adapt the underlying product development processes and systematically make use of additive manufacturing in order to identify opportunities for new products and business cases. In this context, the uncertainty, risks, and capital investments required for the launch of new and innovative product concepts is also reduced. In the near future ALPA Capaul & Weber AG aims at further advancing their products employing the advantages of additive manufacturing.

Manuel Biedermann

pd|z Product Development Group Zurich

Phone

+41 44 632 46 59