Application of blue laser in additive manufacturing of metallic parts

2022 (Spring) Channel: General ideas an needs in the field of additive manufacturing

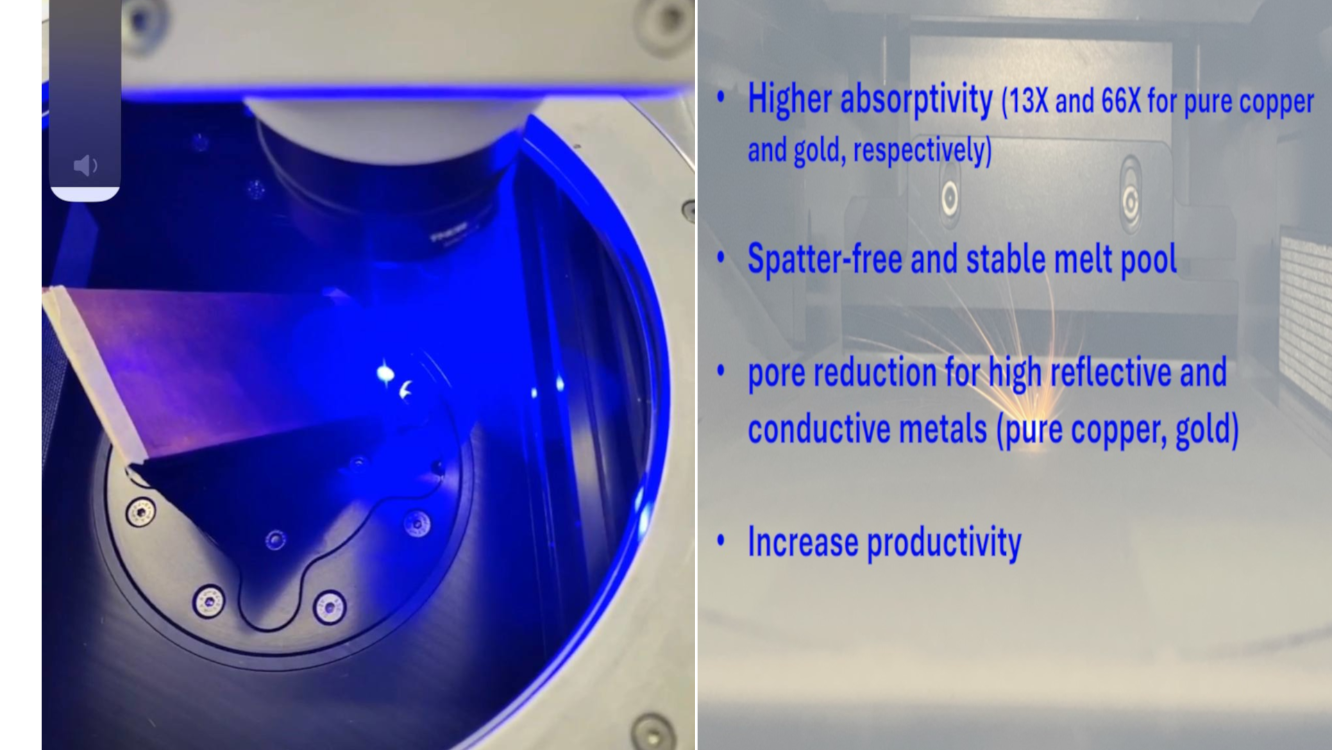

Additive manufacturing (AM) enables the production of intricate internal and external geometries unattainable by conventional manufacturing methods. These can be achieved with short production times and minimal custom tooling. Among different AM techniques, the laser powder bed fusion (LPBF) process has received the most focus. The application of this technology to high reflective metals and alloys, like copper, has been demonstrated with the use of high-power NIR laser. At the typical wavelength around 1070nm it is necessary to work in strong keyhole mode for efficient energy deposition in the material thereby compensating for the low bulk absorptivity of copper. This process is inefficient and tends to be unstable, thus leading to porosity, low dimensional accuracy, and high energy consumption.

The idea of this project is to do a feasibility study for integrating a fiber-coupled blue laser (pre-series high brilliance model but low power) on a LPBF station and compare the efficiency of the process with classical infrared laser installed on commercial LPBF machine. Absorptivity of the blue light for reflective alloys is more than ten times higher than for infrared. Blue lasers have already been shown to offer benefits in welding high-reflective metals in different sectors such as electronic. We believe that blue laser will solve some intractable problems and increases the productivity for manufacturing LPBF part of reflective and other engineering alloys as well.