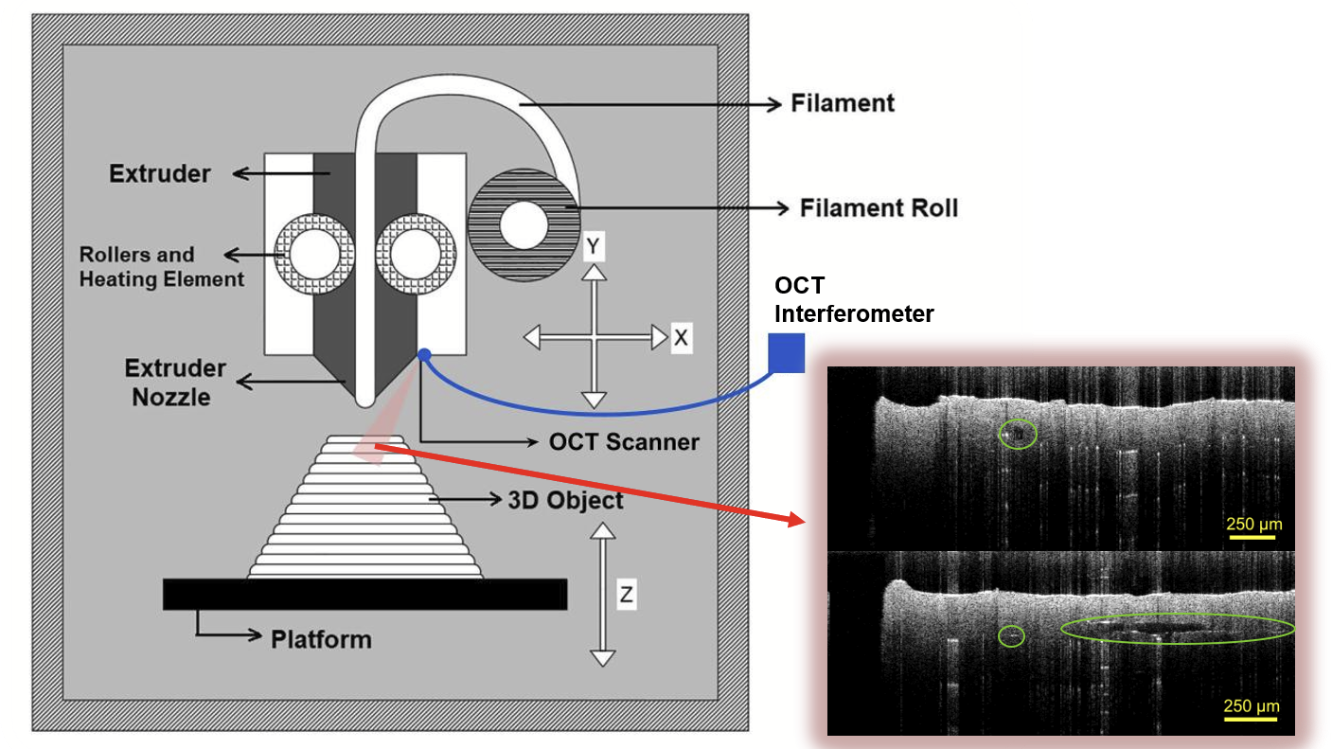

Photonic In-Situ Quality Monitoring of Additive Manufacturing

2021 (Autumn) Channel: General ideas and needs in the field of additive manufacturing

The goal of this project is to develop an economical optical coherence tomography system paired with computer vision algorithms for in-situ quality monitoring in desktop FFF printers. The photonic in-situ quality monitoring enables real-time detecting of errors sub-surface at micrometer scale and could be used to quantify adhesion between layers. It could establish reproducible quality standards in 3D printed parts that are essential for large scale commercial adoption of the technology.

A successful outcome is creating a cheap and easily implementable OCT system that performs in-situ structural quality monitoring, is able to integrate with optical camera systems for a complete picture of the part quality from macroscopic to sub-micron scale, and opens up possibilities for in-situ NDT and part validation as well.