Novel X-ray detector for real-time quality control in EBAM

Channel: General ideas and needs in the field of additive manufacturing

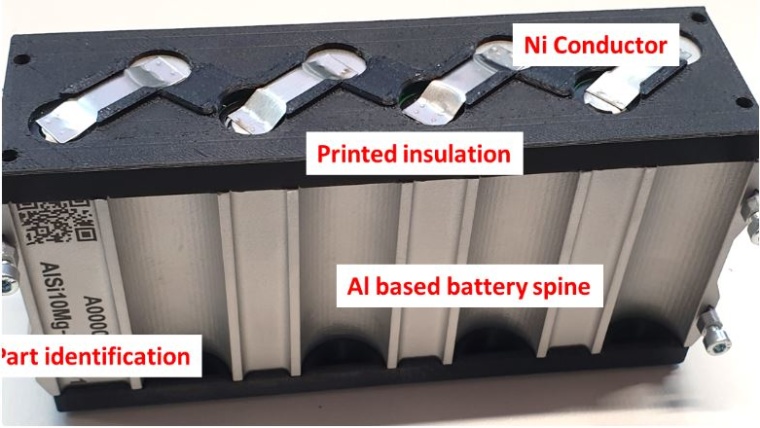

The present feasibility study will focus on the real-time X-ray imaging of defects in metal-to-metal Electron Beam Additive Manufacturing (EBAM). Indeed, the real-time detection of defects will allow for an immediate repair or at least for stopping the process to avoid wasting time, energy and material.

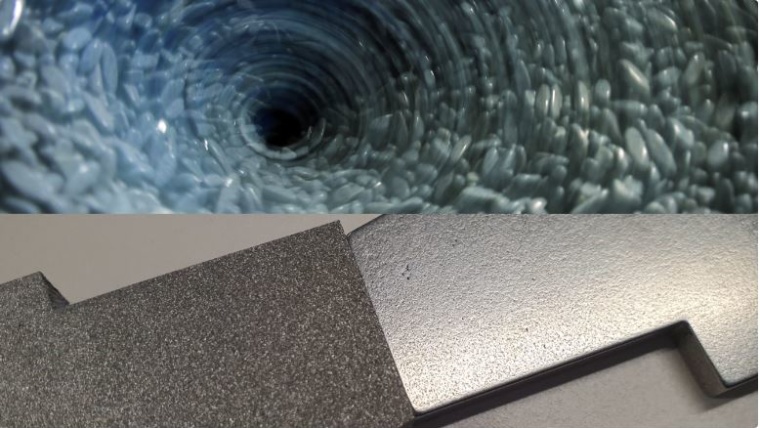

An EBAM machine is part of the equipment of the Laboratory for Advanced Materials Processing at EMPA. It is planned to perform real-time X-ray imaging of samples in production. The idea came up to use the X-rays produced by the melting electron beam to image the environment of the meltpool during processing. The melt is an ellipsoidal melt volume with a central vapor capillary induced by evaporation of metal by the electron beam. The electron beam enters the capillary being scattered but most of the electrons hit the bottom of the capillary solid metal that acts as X-ray source. The emission volume is supposed to be small enough to be considered as a point source. X-ray images of the meltpool will be capture thanks to the ETHZ perovskite detector (hard X-rays) and a germanium detector (soft X-rays and potentially SWIR).

Perovskite was identified as an ideal potential candidate for non-destructing X-rays applications. We were lucky enough to come in touch with the Kovalenko Lab at ETHZ [1] that already participated in other Microtech Booster projects initiated by IRIS Switzerland [2-3]. This solution allows for direct conversion, low temperature processes, wide detection area and affordable sensor manufacturing.

First results obtained within the Microtech Booster framework [2] suggest that the perovskite detector used for the experiment could potentially replace any CZT detector, at least for relatively low-energy applications. A new perovskite detector version comprising 256 pixels is currently being developed at ETHZ that should help to propose first commercial solutions, i.e. for composite aircraft parts or closed luggage inspection.